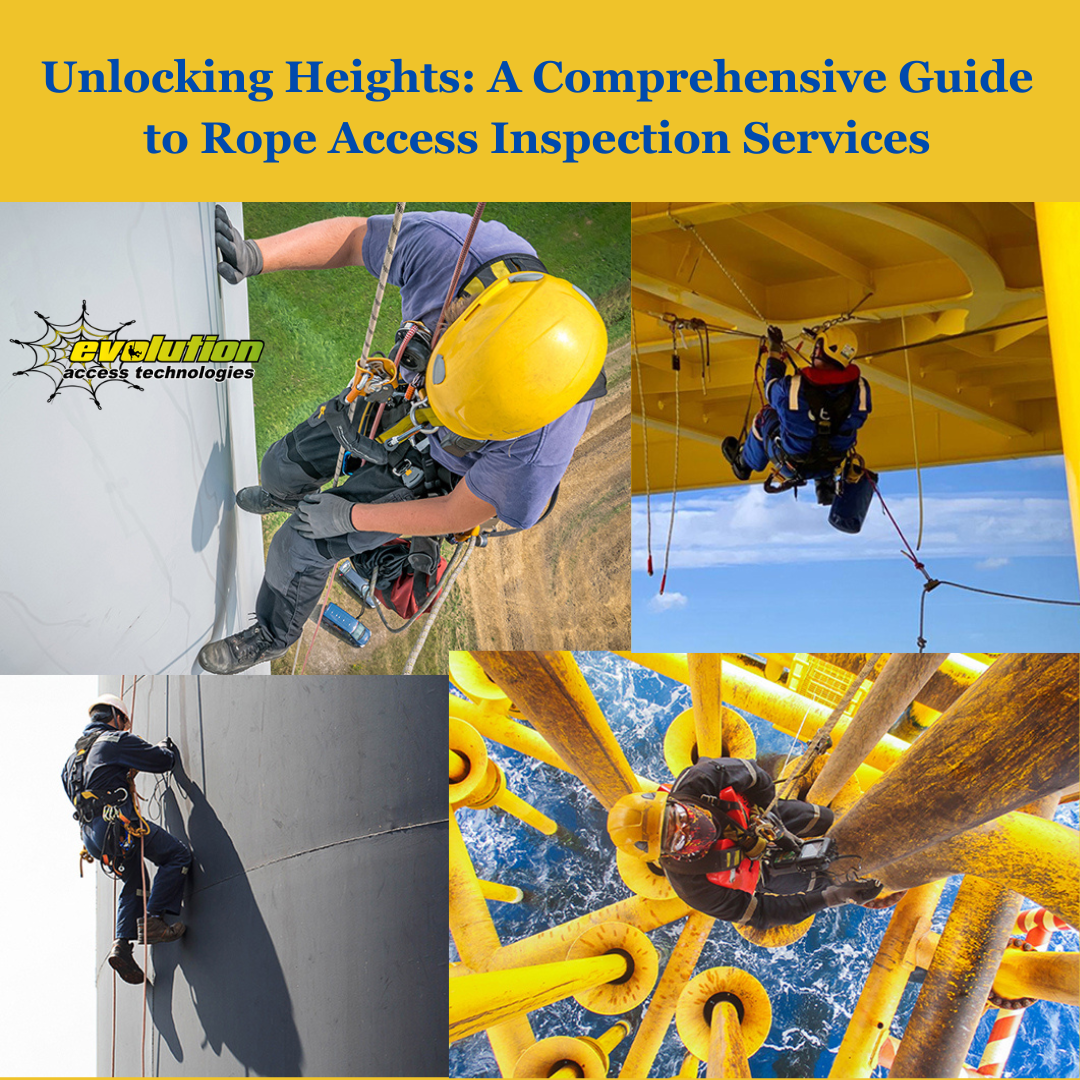

In today’s rapidly evolving industrial landscape, industrial rope access has become a go-to solution for safe and efficient work at height — especially in sectors like construction, offshore platforms, civil infrastructure, and renewables. Designed to minimize risks while maximizing accessibility, this technique has revolutionized how companies handle inspection, maintenance, and repair tasks in hard-to-reach places.

Whether you’re managing complex offshore operations or maintaining tall onshore facilities, rope access provides unmatched versatility, cost-effectiveness, and safety when executed by trained professionals.

What is Industrial Rope Access?

Industrial rope access is a system of work positioning techniques derived from climbing and caving methods. It allows trained technicians to access high or difficult areas using ropes, harnesses, and specialized safety equipment — eliminating the need for traditional access solutions like scaffolding or heavy machinery.

Unlike conventional access systems, rope access offers:

- Rapid setup and dismantling

- Minimal ground footprint

- Enhanced safety when following IRATA guidelines

- Lower project cost

Why Choose Industrial Rope Access Over Traditional Methods?

Choosing rope access over scaffolding, aerial lifts, or cranes is often not just a matter of convenience — it’s a strategic decision. Here’s why:

1. Greater Safety Standards

- Rope access has one of the lowest incident rates in the access industry.

- Double-rope systems always ensure backup support.

- Operators undergo rigorous IRATA training.

2. Faster Mobilization

- Ideal for projects that require quick deployment.

- Minimal time is spent setting up compared to scaffolding.

3. Cost-Efficiency

- Reduces labor, equipment, and setup costs.

- Avoids obstructing daily operations at the job site.

4. Flexibility in Challenging Environments

- Perfect for confined spaces, tall structures, offshore rigs, and complex industrial setups.

Applications Across Industries

Rope access is not a one-size-fits-all solution — it’s incredibly adaptable. Here’s how it applies across the major industries Evolution Access serves:

Oil & Gas

- Flare stack inspections

- Tank maintenance

- NDT (Non-Destructive Testing) at height

Renewables (Wind & Solar)

- Blade inspections and repairs

- Solar panel cleaning at elevation

- Lightning protection system checks

Marine

- Hull inspections

- Corrosion monitoring

- Port facility maintenance

Geotechnical & Civil

- Bridge inspections

- Slope stabilization

- Dam wall surveys

Construction

- Facade maintenance

- Expansion joint repairs

- Post-construction inspections

Core Services Offered with Rope Access

At Evolution Access, our rope access professionals are skilled in providing a wide range of support services, such as:

Inspection

- Structural assessments

- Thermal imaging

- Ultrasonic testing

- Visual checks for corrosion, cracks, or damage

Maintenance & Repair

- High-rise cleaning

- Painting and coating

- Mechanical repair work

- Leak detection and sealing

Installation

- Signage installation

- Fall protection system setup

- Electrical component mounting

These services are performed in accordance with industry safety standards and tailored to each client’s project needs.

Benefits of Partnering with Certified Rope Access Experts

Partnering with trained rope access professionals ensures:

- Compliance with IRATA standards

- Reduced downtime and operational disruption

- Minimal environmental impact (ideal for sensitive sites)

- Customizable solutions for your specific industry

At Evolution Access, our technicians are not just climbers — they’re multi-skilled tradespeople who specialize in various disciplines like welding, NDT, rigging, and electrical work. This multi-competency approach ensures fewer personnel on-site, faster project turnaround, and better value.

How to Know If Your Project is Suitable for Rope Access

Not every project is a perfect match — but many are. Here’s a checklist to determine if rope access might be right for you:

- Is the area hard to reach using conventional equipment?

- Are you looking to reduce setup and teardown time?

- Do you need highly skilled technicians to perform the task at height?

- Are you concerned about minimizing safety risks?

If you answered yes to any of these, rope access could be your most efficient and cost-effective solution.

Choosing the Right Rope Access Provider

When choosing a rope access company, consider the following:

- Certification & Training: IRATA certification is non-negotiable.

- Experience in Your Industry: Ensure they understand the specific challenges in your sector.

- Safety Record: Look for a provider with a track record of zero major incidents.

- Technical Expertise: Rope access is only part of the solution — technicians should be skilled in inspections, repairs, and installations.

Evolution Access brings years of cross-industry experience backed by a strong commitment to safety, compliance, and client satisfaction.

Conclusion:

Industrial rope access is not just an alternative method — it’s the future of safe, smart, and agile access for high-risk and high-reach jobs. It allows professionals to reach places that were previously inaccessible or unsafe using traditional means — all while minimizing costs and maximizing efficiency.

At Evolution Access, we combine advanced rope access techniques with hands-on industry expertise across construction, oil & gas, civil infrastructure, marine, renewables, and more. If your project demands precision, speed, and safety — we’re ready to scale new heights with you.

Commonly Asked Questions:

What are the advantages of rope access ?

What is rope access inspection ?

How to train your team to meet rope access safety requirements ?