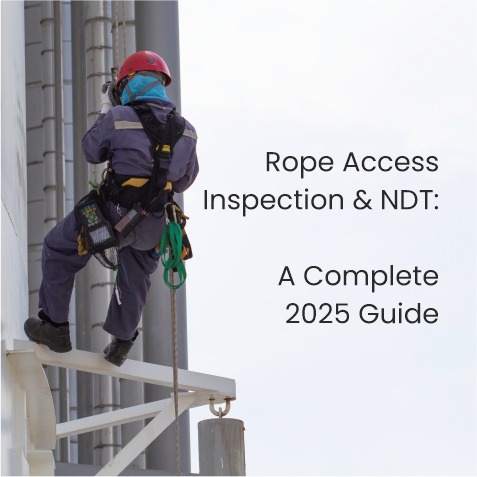

Traditional maintenance methods like scaffolding, heavy lifts, or rope‑suspended platforms often mean long setup times, high labour costs, and extended downtime. Evolution Access brings a smarter solution: industrial rope access.

Using certified IRATA technicians, rope access allows direct vertical and confined-space entry without scaffolding or crane setups. This reduces manpower requirements, eliminates unnecessary equipment, and ensures tasks are completed faster — often cutting maintenance costs and downtime up to 50%.

Explore our rope access services to see how we serve industrial, offshore, and renewable projects efficiently.

______________________________________________________________________________________________________________

Faster, Safer, and More Flexible

One of the major benefits of rope access is speed and flexibility. Technicians can reach hard-to-access areas on tall structures, offshore platforms, or industrial facilities without dismantling existing infrastructure.

- Reduced downtime: Equipment or plant shutdowns are minimized, keeping operations running.

- No heavy machinery required: Saves rental and operational costs of cranes or lifts.

- Safety-first approach: IRATA-certified rope access reduces risks compared to makeshift scaffolds.

Check out our offshore rope access solutions for detailed industry-specific applications.

______________________________________________________________________________________________________________

Real-World Use Cases

Across oil & gas, marine, and industrial sectors, rope access has proven its value:

- Offshore platforms: Rapid inspection and maintenance with minimal vessel or platform downtime.

- Industrial plants: Maintenance of large machinery, chimneys, or storage tanks without halting production.

- Renewables: Wind turbines or solar panel inspections done efficiently at height.

By choosing rope access, companies save on labour, equipment hire, and project overruns, while maintaining top-notch safety and operational standards.

______________________________________________________________________________________________________________

Why Evolution Access?

Evolution Access stands out with:

- Certified technicians (IRATA Level 1, 2, 3)

- Advanced equipment & rope systems for safe, reliable access

- Nationwide service across offshore, industrial, and renewable projects

- Proven track record in reducing downtime and operational costs

Discover our industrial rope access services to plan your next maintenance project smarter.

______________________________________________________________________________________________________________

FAQs

Q1: How much can rope access actually save compared to traditional methods?

A: Depending on the project scale, rope access can reduce labor, equipment, and setup costs by up to 50%, and minimize downtime significantly.

Q2: Is rope access safe for industrial maintenance at height?

A: Yes. All technicians are IRATA-certified, use tested safety equipment, and follow strict safety protocols, making rope access safer than scaffolding or cranes for many tasks.

Q3: Which industries benefit most from rope access?

A: Rope access is ideal for oil & gas, marine, industrial plants, renewables, and large commercial infrastructure, especially where conventional access methods are time-consuming or costly.