A Story from the Onshore Frontlines

Picture this: You’re managing a busy port terminal on India’s eastern coast. The monsoons are fierce. Salt-heavy air corrodes steel faster than you imagined. A critical support beam beneath a jetty starts flaking—and the next shipload arrives in 48 hours.

What do you do?

You don’t have the time to erect scaffolding. Cranes won’t reach that spot. The clock is ticking, and the pressure is mounting.

That’s when onshore rope access steps in—swift, safe, and surgically precise.

What Are Onshore Rope Access Services?

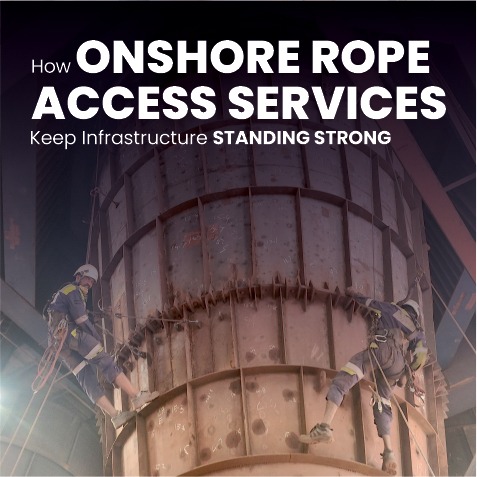

Onshore rope access is a high-efficiency method of working at height—or in hard-to-reach places—without traditional scaffolding or mechanical lifts. Using harnesses, ropes, and highly skilled technicians, these services allow for inspections, repairs, cleaning, and installations on infrastructure based on land or near coastal environments.

And unlike offshore access, which deals with open seas, oil rigs, and oceanic wind farms, onshore rope access focuses on complex, land-based structures—yet still operates in high-risk zones like:

- Coastal jetties and terminals

- Industrial tanks and silos

- Bridges, turbines, and chimneys

- Refineries and high-rise facilities

- Ports, harbors, and marine infrastructure

The Harsh Reality of Onshore Coastal Infrastructure

Salt air. High humidity. Monsoon winds. Corrosive grime.

Maintaining assets near the coastline isn’t just challenging—it’s relentless. These environments accelerate wear and tear, leading to:

- Corrosion in steel structures

- Weakening of joints and welds

- Surface damage from waterlogging

- Frequent need for repainting and reinforcement

- Urgent inspections to meet safety compliance

Now layer on the operational demand: zero room for shutdowns, tight schedules, and cost constraints.

Traditional solutions like scaffolding or boom lifts? Too slow. Too expensive. Too disruptive.

This is where rope access shines.

Why Rope Access Over Traditional Methods?

Let’s compare:

|

Feature |

Rope Access | Scaffolding | Cranes |

|

Setup Time |

A few hours | Several days |

Days (if feasible) |

|

Mobility |

High | Limited |

Fixed reach |

|

Site Disruption |

Minimal | Major |

Moderate |

|

Cost |

Cost-effective | Expensive |

Very expensive |

|

Safety |

High (with IRATA standards) | Variable |

Depends on crew |

| Access Capability | Complex/vertical/restricted areas | Only what it can be built around |

Limited reach |

Rope access wins—especially when time, safety, and budget are critical.

What Do Onshore Rope Access Services Include?

At Evolution Access, our onshore teams are IRATA-certified, trained for high-risk environments, and equipped to deliver precision work with minimal disruption. Here’s what our services typically cover:

Structural Inspections

- Visual surveys

- Close-range checks

- Ultrasonic thickness testing

- Photographic & video documentation

Non-Destructive Testing (NDT)

- Magnetic Particle Testing

- Dye Penetrant Inspection

- Eddy Current Testing

Surface Preparation & Repairs

- Corrosion removal

- Minor patchwork

- Painting & coating

- Welding in confined spaces

Cleaning & Maintenance

- Debris removal

- Pressure washing

- Tank and silo cleaning

Custom Installations

- Fall arrest systems

- Signage and electrical

- Safety nets and rigging

Common Onshore Pain Points We Solve

You might relate to these:

- “Our tank inspection has been pending for weeks due to access issues.”

- “We can’t afford to stop operations just to check corrosion under the jetty.”

- “The cost of building scaffolding is more than the actual repair job.”

- “Every minute our plant is offline, we lose lakhs.”

You’re not alone. We’ve heard this from coastal plants, oil terminals, power stations, and infrastructure firms. And we’ve responded—with rapid deployment, zero scaffolding, and 100% compliance.

Real-World Example: Dockside Repairs Without Downtime

Recently, a marine terminal in Gujarat called us with a problem:

Corrosion was building up beneath their loading arms—completely inaccessible from land or standard lifts.

Scaffolding setup would take over a week, shut down operations, and cost depending upon on the projects.

Instead, our onshore rope access team was deployed within 48 hours. In two days, we:

- Completed a full inspection

- Identified critical corrosion points

- Executed minor repairs and coating

- Provided a detailed assessment report

No shutdown. No disruption. No unnecessary cost.

Who Are Our Rope Access Technicians?

They’re not just climbers. They’re experts.

Every team member is:

- IRATA Level I–III certified

- Trained in first aid and emergency rescue

- Skilled in both access and trade disciplines (inspection, welding, repair)

- Backed by years of experience in onshore coastal and industrial environments

They don’t just access the problem—they fix it.

How Onshore Rope Access Saves You Time & Money

Let’s break it down:

- Faster turnaround = less downtime

- Minimal setup = lower labor cost

- No scaffolding/crane hire = zero extra rentals

- Multidisciplinary team = no multiple vendors

- Work while operations continue = no production loss

In many cases, clients save up to 40–60% by switching from scaffolding to rope access.

Planning an Onshore Project? Here’s What to Do:

- Inspect Your Site – Identify hard-to-reach zones

- Assess Urgency – Don’t delay critical inspections

- Skip the Scaffolding – Talk to a rope access expert first

- Ask for IRATA Certification – Always work with certified teams

- Request a Demo or Quote – Most reputable providers, like Evolution, will assess and advise you quickly

Ready to Make Onshore Access Safer and Smarter?

From wind farms in Tamil Nadu to harbor terminals in Gujarat, Evolution Access has delivered reliable, rapid, and safe rope access solutions across India.

So, whether you’re racing against corrosion, budgets, or deadlines—our onshore team is ready to anchor your project in success.

Get in Touch

Have a site you need inspected or maintained?

- Email us at marketing@evolution-access.com

- Explore more at www.evolution-access.com

- Pan-India Deployment Available

Let’s raise the bar in maintenance—without lifting a single scaffold pole.