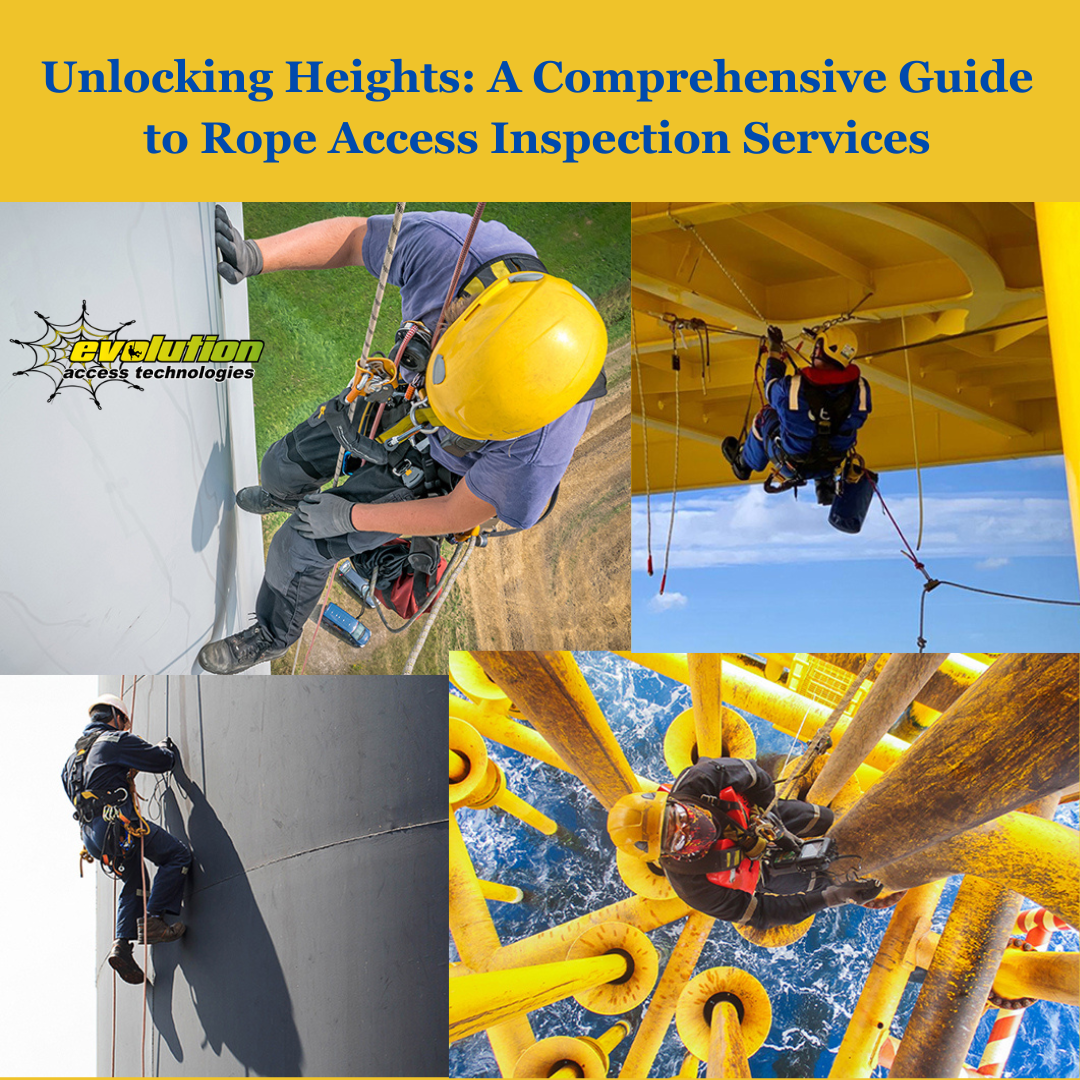

Why Rope Access Is Changing the Game

Picture this: You’re managing a massive industrial site—a wind turbine, a refinery tank, or maybe a high-rise façade. Your team needs to handle maintenance tasks like cleaning, inspection, painting, or repairs.

In the past, your options were bulky scaffolding, cranes, or MEWPs (Mobile Elevating Work Platforms). These work, but they come with baggage—long setup times, high costs, safety concerns, and major site disruption.

Enter rope access—a technique born from industrial climbing. Using a dual-rope system (one for work, one for safety), trained technicians can move up, down, and across structures quickly and securely. It’s fast, flexible, and leaves a light footprint, making it the go-to solution for tight schedules or tricky locations.

When Rope Access Makes More Sense

Rope access isn’t always the answer, but it’s the smart choice when:

- Speed matters – Rope systems can be set up in hours, not days.

- Space is tight – Works where cranes and scaffolding simply can’t fit.

- Downtime must be minimized – Jobs are often done 30–50% faster.

- Safety is critical – Certified technicians follow strict protocols and use backup systems.

- Disruption must stay low – Minimal noise, no heavy machinery, and no blocked pathways.

That said, scaffolding or cranes might still be better for:

- Heavy-duty jobs needing large staging areas

- Long-term projects where scaffolding provides weeks of stable access

- Tasks involving heavy materials or internal lifts

The Rope Access Process: From Start to Finish

1. Define the job

What needs doing—inspection, repairs, or a deep clean? How high? How complex? Are there time limits or operational constraints?

2. Compare access methods

Make a simple checklist:

- Setup time

- Cost

- Safety

- Downtime

- Environmental impact

(Often, you’ll find rope access is quicker, safer, and cheaper—especially for short-term jobs.)

3. Choose certified professionals

Only work with IRATA or SPRAT-certified Ask for:

- Method statements & risk assessments

- Proof of technician levels (Level 1, 2, or 3)

- Rescue plans and insurance

4. Site visit & planning

Your provider inspects the site, identifies safe anchor points, and creates a clear risk assessment and method statement (RAMS)—including equipment lists and emergency procedures.

5. The work begins

A small team rigs rope and gets to work. Because ropes can be moved easily, jobs like inspections, cleaning, and light repairs happen efficiently, with minimal disruption to the site.

6. Wrap-up & review

Once the job’s done, everything is dismantled in minutes. You get a completion report with any issues flagged and suggestions for future maintenance.

Rope Access vs. Traditional Methods

Here’s how rope access stacks up against scaffolding and cranes:

|

Metric |

Rope Access |

Scaffolding / Crane |

|

Setup time |

Minutes to hours |

Days |

|

Crew size |

Small team, minimal gear |

Large crew, heavy equipment |

|

Cost |

30–70% cheaper |

Higher (labour + rentals) |

|

Downtime |

Minimal |

Often significant |

|

Safety |

Very low (backup ropes, training) |

Moderate |

|

Flexibility |

Works on awkward shapes & spaces |

Limited reach |

| Environmental impact |

Low noise & material use |

High materials, noise, traffic |

The bottom line: Rope access can save time, reduce costs, and improve safety.

What to Look for in a Rope Access Partner

A cheap quote isn’t enough—you need professionalism and global safety standards.

Look for:

- IRATA-certified companies with proven audits

- Technicians trained to Level 1, 2, or 3 (with Level 3 overseeing safety)

- Full method statements and rescue plans for every job

- Insurance and proper equipment (no cutting corners)

For example, Evolution Access stands out by combining rapid deployment, minimal ground footprint, and strict IRATA compliance—serving sectors from wind energy and marine to oil & gas and infrastructure.

A Real-World Example

Imagine a solar farm operator needing blade repairs on 30 turbines.

- Old way: Scaffolding or cranes, taking 6–8 weeks per turbine—plus weather delays, blocked access, and massive costs.

- Rope access way: A small IRATA-certified crew rigs each turbine in under an hour, completing cleaning, inspection, and repairs in 1–2 days per turbine.

- Project finished in under 3 weeks

- Costs cut by 40–60%

- Minimal downtime and environmental disruption

Technicians even caught early signs of corrosion—helping the operator shift to preventive maintenance instead of costly reactive fixes.

How to Make Rope Access Part of Your Maintenance Plan

Don’t think of rope access as a one-time fix. Build it into your long-term strategy:

- Audit your assets – Find the tricky, high-maintenance areas.

- Create a decision matrix – Compare methods by cost, time, safety, and impact.

- Pre-qualify providers – Build a network of trusted IRATA-certified partners.

- Plan proactive inspections – Use rope access for regular low-cost checks.

- Log inspection data – Feed findings into your asset management software.

- Review & refine – Track results, adjust, and improve for the next job.

Why Choose Evolution Access

If you’re reading this on Evolution Access, here’s why we’re the right partner:

- Expertise across industries: renewables, oil & gas, marine, and infrastructure

- IRATA-aligned training and strict safety protocols

- Fast, efficient setups with minimal disruption

- Full inspection & reporting capabilities—NDT, thermal imaging, coatings, and more

Final Thoughts

Rope access isn’t just another maintenance option—it’s a smarter way to work.

- Faster – Less setup, less downtime

- Safer – Certified technicians, strict safety measures

- Cheaper – Lower overall project costs

- Cleaner – Minimal noise, mess, and site disruption

By integrating rope access into your maintenance strategy, you’re not just fixing problems—you’re future-proofing your operations.

If you manage assets where time, safety, and efficiency matter, rope access isn’t just the right choice—it’s the strategic choice.

Contact Us:

Address Location

- GK Terminal, Floor 1 & 2 Poonamallee High Road, Nerkundram Chennai, Tamil Nadu 600107