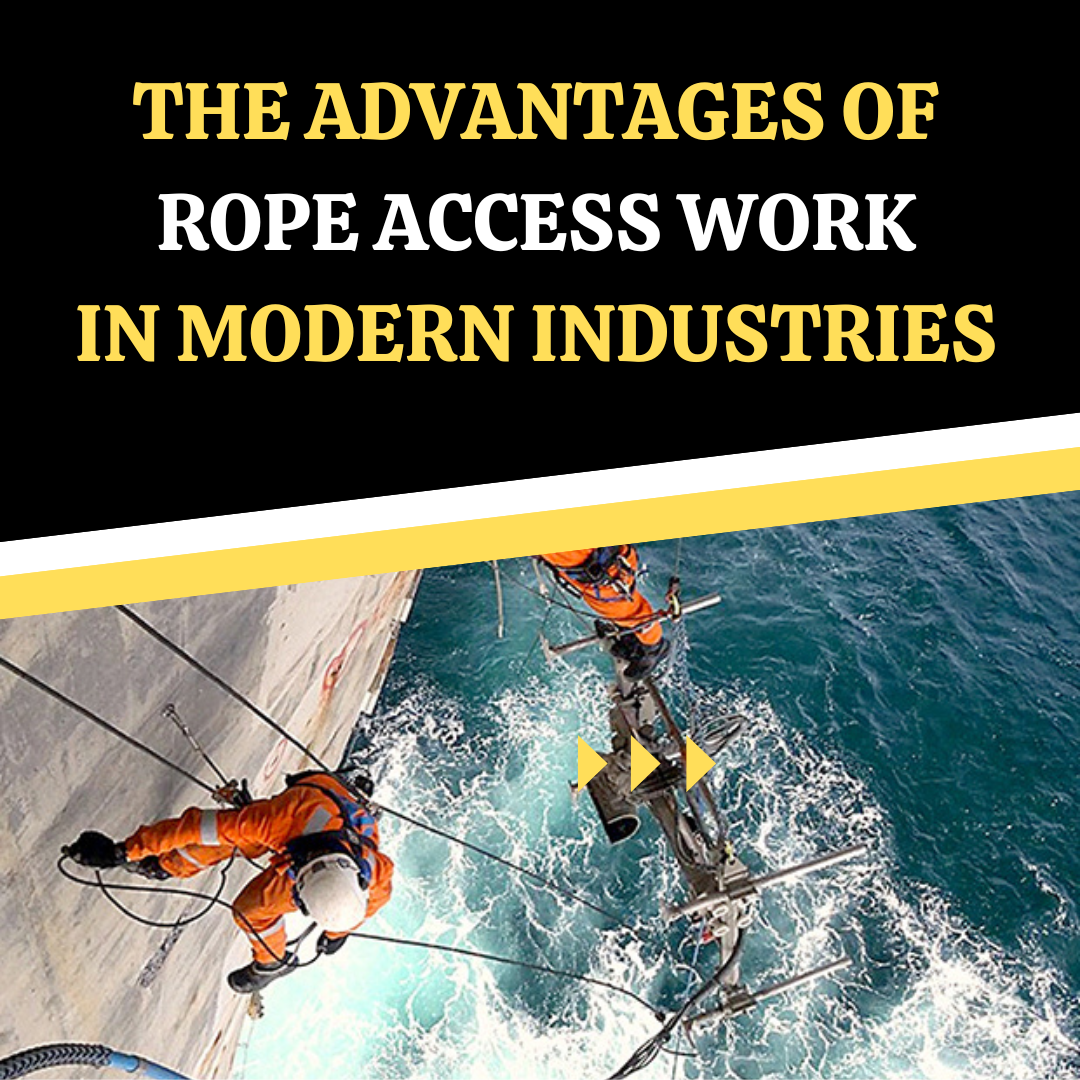

Rope access work has revolutionized modern industries, enabling workers to scale new heights quickly and efficiently. Gone are the days of relying solely on scaffolding or cranes to access hard-to-reach locations. With rope access techniques, workers can quickly and safely access even the most challenging areas, such as skyscrapers, bridges, and wind turbines.

The advantages of rope access work are abundant. Firstly, it offers significant cost savings compared to traditional access methods. With minimal equipment and workforce needed, project budgets can be drastically reduced without compromising safety. Secondly, rope access work is highly versatile, making it suitable for various industries, including construction, oil and gas, and maintenance.

Additionally, rope access work provides greater flexibility and speed regarding project execution. Workers can swiftly move from one location to another, minimizing downtime and increasing productivity. Moreover, rope access work is environmentally friendly, reducing the need for heavy machinery and its associated emissions.

In conclusion, rope access work offers numerous advantages in modern industries, from cost savings to increased efficiency and environmental benefits. As technology progresses, this versatile approach to working at heights will continue to scale new heights and drive industry innovation.

As technology advances, the future of rope access work in modern industries looks promising. One trend that can be expected is the integration of robotics and automation into rope access work. This will allow for even greater precision and efficiency in completing tasks. For example, drones equipped with rope access capabilities can inspect and maintain structures inaccessible by traditional means. Additionally, advancements in materials science may lead to the development of even more robust and lighter ropes, further enhancing the capabilities of rope access work.

Another future trend in rope access work is the adoption of virtual reality (VR) and augmented reality (AR) technologies. These technologies can provide remote assistance and training to rope access technicians. With VR and AR, experts can guide technicians in real time, regardless of their physical location. This improves worker safety and reduces travel costs and downtime associated with on-site training.

The advantages of rope access work are abundant and have contributed to its growing popularity in modern industries. Firstly, it offers significant cost savings compared to traditional access methods. Unlike scaffolding or cranes, which require extensive setup and dismantling, rope access work requires minimal equipment and workforce. This translates to reduced project budgets without compromising safety. Additionally, the versatility of rope access work makes it suitable for a wide range of industries, including construction, oil and gas, and maintenance.

Secondly, rope access work provides greater flexibility and speed in project execution. Workers can swiftly move from one location to another, using ropes to reach their desired work areas. This minimizes downtime and increases overall productivity. Whether conducting inspections, performing repairs, or carrying out installations, rope access work allows for efficient and agile project management.

Furthermore, rope access work is environmentally friendly. Traditional access methods often involve heavy machinery, which consumes energy and emits harmful emissions. In contrast, rope access work eliminates the need for such machinery, reducing the environmental impact of industrial operations. This makes it a sustainable and eco-friendly choice for accessing heights in various industries.

Safety is paramount in rope access work, and strict safety measures are implemented to ensure the well-being of workers. One key safety aspect is the use of Personal Protective Equipment (PPE). Rope access technicians are equipped with harnesses, helmets, and other necessary gear to protect them from falls and other hazards. These PPEs are designed for rope access work and comply with industry safety standards.

In addition to PPE, rope access technicians undergo rigorous training and certification programs. These programs cover various aspects of rope access work, including rope techniques, rescue procedures, and first aid. By equipping workers with the necessary knowledge and skills, companies can ensure higher safety during rope access operations.

Another essential safety measure in rope access work is the implementation of thorough risk assessments. Before any work is carried out, a comprehensive work area assessment is conducted to identify potential hazards and develop appropriate control measures. This proactive approach to safety helps mitigate risks and prevent accidents or injuries.

Rope access work applies to various industries, each benefiting from its unique advantages. In the construction industry, rope access techniques are commonly used for building maintenance, inspections, and repairs. With ropes, workers can access every corner of tall structures, ensuring their structural integrity and identifying potential issues.

The oil and gas industry also greatly benefits from rope access work. Offshore platforms and rigs require regular inspections and maintenance, often in challenging conditions. Rope access techniques provide a cost-effective and efficient solution for these tasks, minimizing downtime and maximizing productivity.

Additionally, the wind energy industry relies heavily on rope access work to inspect and maintain wind turbines. These structures are often located in remote and difficult-to-reach locations, making traditional access methods impractical. Rope access technicians can quickly ascend and descend wind turbines, ensuring their proper functioning and prolonging their lifespan.

Rope access work requires specialized equipment and tools to ensure the safety and effectiveness of operations. One key component is the rope itself. Modern ropes used in rope access work are made of high-strength materials such as aramid fibres or polyester. These ropes have excellent tensile strength and durability, allowing workers to rely on them even in challenging conditions.

Harnesses are another essential piece of equipment used in rope access work. They are designed to distribute the weight and forces exerted on the body during rope access operations. Harnesses are adjustable and have multiple attachment points, allowing workers to secure themselves to the ropes and maintain stability while working at heights.

Other tools commonly used in rope access work include descenders, ascenders, and carabiners. Descenders are used for controlled descents, while ascenders assist workers in ascending ropes. Carabiners are used to attach equipment and connect ropes. These tools are designed to be lightweight, durable, and easy to use, enhancing the efficiency and safety of rope access operations.

One critical advantage of rope access work is its cost-effectiveness compared to traditional access methods. Conventional methods, such as scaffolding or cranes, often require significant setup and dismantling time, as well as the use of additional equipment and labour. In contrast, rope access work requires minimal equipment and can be set up quickly, reducing project costs.

The reduced setup time also translates to increased productivity. With rope access techniques, workers can access work areas more efficiently, minimizing downtime and maximizing the time spent on tasks. This increased efficiency saves costs and allows projects to be completed within shorter timeframes.

Furthermore, rope access work’s versatility contributes to its cost-effectiveness. Whether a small-scale maintenance task or a large-scale construction project, rope access techniques can be adapted to suit various requirements. This eliminates the need for specialized access equipment, which can be expensive to purchase or hire.

Rope access work offers numerous advantages in modern industries, from cost savings to increased efficiency and environmental benefits. As technology progresses, this versatile approach to working at heights will continue to scale new heights and drive industry innovation. Integrating robotics, virtual, and augmented reality into rope access work will enhance its capabilities and safety.

Industries such as construction, oil and gas, and wind energy will continue to benefit from the cost-effectiveness and versatility of rope access techniques. With improved safety measures, rigorous training programs, and advanced equipment, rope access work will remain reliable and efficient for accessing heights and performing various tasks. As the world continues to build taller structures and explore challenging environments, rope access work will play a crucial role in ensuring the safety and success of modern industries.

How are emergency procedures and rescue techniques handled in rope access work?

How to choose a reputable rope access inspection company?