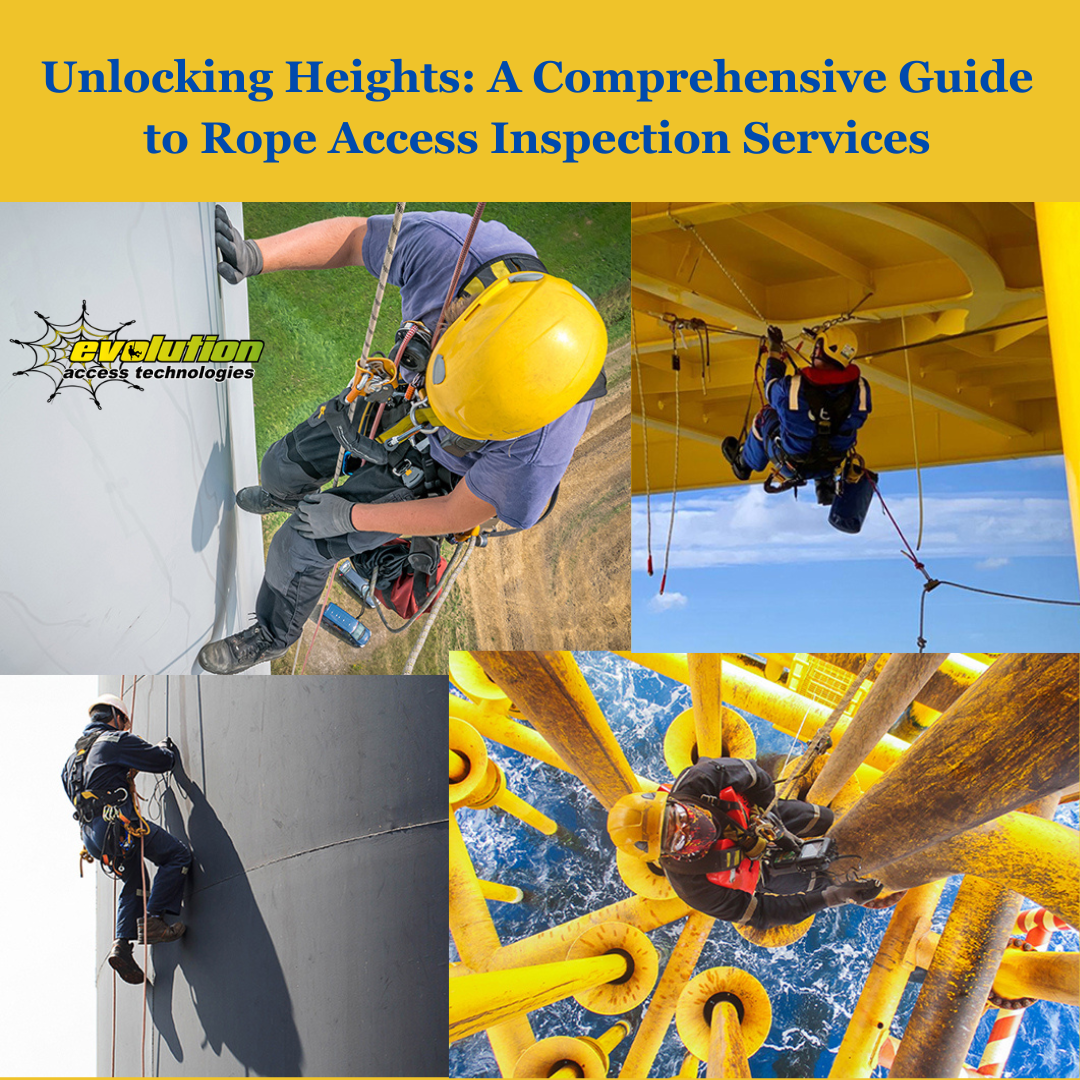

If you’re looking for a safe and efficient way to conduct inspections in difficult-to-reach areas, rope access inspection services offer the perfect solution. From towering skyscrapers to complex industrial structures, these specialized technicians utilize rope access techniques to reach heights that traditional methods cannot.

In this comprehensive guide, we’ll delve into the world of rope access inspection services, exploring the benefits and applications of this unique approach. We’ll examine how rope access can provide cost-effective solutions for various industries, including construction, oil and gas, and power generation.

Our expert team will also investigate the safety protocols and training involved in rope access inspections, ensuring that quality standards are met and maintained. From visual inspections to non-destructive testing, we’ll uncover the various techniques to assess structural integrity and identify potential risks.

Rope access inspection involves using ropes, harnesses, and other safety equipment to access difficult-to-reach areas. Unlike traditional scaffolding or cranes, rope access allows technicians to easily navigate vertical, horizontal, and overhead surfaces.

Rope access inspections are commonly used in construction, oil and gas, power generation, and even entertainment industries. These inspections can include visual assessments, non-destructive testing, and other techniques to evaluate the structural integrity of buildings, bridges, towers, and other structures.

One critical advantage of rope access inspection is its versatility. Technicians can access areas that would be otherwise inaccessible, saving both time and money. Additionally, the nonintrusive nature of rope access minimizes disruption to ongoing operations, making it an ideal choice for inspections in sensitive or high-traffic environments.

When selecting a rope access inspection company, you must ensure that you’re working with a reputable and experienced provider. Here are some key factors to consider when making your decision:

1. Safety Record: Safety should be a top priority for rope access inspection services. Look for companies with a proven track record of adhering to safety protocols and maintaining high safety standards. Check for certifications such as SPRAT (Society of Professional Rope Access Technicians) or IRATA (Industrial Rope Access Trade Association).

2. Industry Experience: Consider the company’s experience in your specific industry. Different industries have unique requirements and regulations, so it’s important to work with a company that understands your sector’s challenges and complexities.

3. Qualified Technicians: Verify that the company employs technicians trained and certified in rope access techniques. Look for certifications such as SPRAT Level 1, 2, or 3, or IRATA Level 1, 2, or 3. These certifications ensure that the technicians have undergone rigorous training and have the necessary skills to perform inspections safely and effectively.

4. Equipment and Technology: Inquire about the equipment and technology used by the company. Using state-of-the-art equipment and advanced technology can enhance the efficiency and accuracy of inspections. Ask about the company’s maintenance practices to ensure their equipment is well-maintained and up-to-date.

Considering these factors, you can confidently select a reputable rope access inspection company that meets your needs and requirements.

Training and certification play a crucial role in ensuring the safety and competence of rope access inspectors. Technicians undergo rigorous training programs that cover a wide range of topics, including rope access techniques, equipment usage, rescue procedures, and safety protocols.

Industry-recognized organizations such as SPRAT and IRATA typically provide rope access inspector certification. These organizations set the standards for rope access training and certification, ensuring that technicians are well-trained and competent.

The certification process typically involves theoretical knowledge and assessment of practical skills. Technicians must complete specific training hours and demonstrate their abilities in various rope access scenarios. Certification levels, such as SPRAT Level 1, 2, or 3, or IRATA Level 1, 2, or 3, indicate the technician’s proficiency and experience in rope access inspections.

Regular recertification is also required to ensure that inspectors stay current with the latest industry standards and best practices. This ongoing training and certification process guarantees that rope access inspectors are equipped with the knowledge and skills necessary to perform their duties safely and effectively.

Rope access inspections require specialized equipment and tools to ensure the safety and efficiency of the technicians. Here are some of the vital equipment and tools commonly used in rope access inspections:

1. Harnesses: Harnesses are worn by technicians and provide support and fall protection. They are essential for maintaining balance and stability while working at heights.

2. Ropes: Dynamic ropes provide the necessary strength and flexibility in rope access inspections. They are specially designed to withstand heavy loads and harsh conditions.

3. Anchors: Anchors secure the ropes and provide a stable attachment point. Anchors can be fixed, temporary, or portable, depending on the specific requirements of the inspection.

4. Descenders: Descenders are devices used to control the technician’s descent along the rope. They provide a controlled and safe means of movement during inspections.

5. Safety Lanyards: Safety lanyards connect the technician’s harness to the anchor point, providing an additional layer of protection in case of rope failure.

6. Pulleys: Pulleys redirect the rope and reduce friction, allowing for smoother movement and improved efficiency during inspections.

These are just a few examples of the equipment and tools used in rope access inspections. The selection of equipment depends on the specific requirements of the inspection and the industry in which it is conducted.

Rope access inspection services offer numerous benefits for a wide range of industries. Here are some of the key advantages:

1. Cost-Effectiveness: Rope access inspections are often more cost effective than traditional scaffolding or crane methods. The reduced setup time and minimal equipment requirements result in significant cost savings.

2. Versatility: Rope access techniques allow technicians to access difficult-to-reach areas that would be otherwise inaccessible. This versatility makes rope access inspections suitable for various structures and environments.

3. Minimal Disruption: Rope access inspections minimize disruption to ongoing operations, making them ideal for inspections in sensitive or high-traffic areas. The nonintrusive nature of rope access ensures that regular activities can continue uninterrupted.

4. Efficiency: Rope access techniques enable technicians to move quickly and efficiently, reducing inspection time and improving overall productivity. This efficiency translates into faster inspection results and shorter downtimes.

5. Safety: Safety is paramount in rope access inspections. Technicians undergo extensive training and certification to ensure assessments are conducted with the highest safety standards. Using safety equipment and protocols further enhances the safety of rope access inspections.

In conclusion, rope access inspection services offer a safe, efficient, cost-effective solution for conducting inspections in difficult-to-reach areas. From visual assessments to non-destructive testing, rope access techniques can be applied to various industries and structures.

As technology advances, we can expect further improvements in equipment and tools used in rope access inspections. Automation and robotics may also play a more significant role in the future, enhancing the efficiency and accuracy of inspections.

By unlocking the heights with rope access inspection services, we can revolutionize how we inspect and maintain our built environment. Whether it’s ensuring the safety of skyscrapers or assessing the structural integrity of industrial structures, rope access offers a versatile and innovative solution.

So, if you need inspections in challenging locations, consider the benefits of rope access inspection services. By partnering with a reputable company and utilizing the expertise of trained technicians, you can unlock the heights and ensure the integrity and safety of your structures.

What equipment and tools are used in rope access inspections?

What qualifications do you need to become a certified rope access technician?